Email Us: sales@dredgegeorgia.com

Explore Our High-Performance Dredging Equipment

End-to-End Solutions for Efficient Dredging Projects in Georgia

Our Fleet of Dredging Equipment

At Dredge Georgia, we leverage advanced dredging equipment in Georgia for precise sediment removal, channel deepening, and slurry management. Our fleet includes high-efficiency dredges from EDDY Pump, amphibious excavators from Hawk Excavator, and dewatering systems from DAE Pumps, ensuring optimal excavation and transport. With expertise in hydraulic and mechanical dredging, we integrate CFD modeling and real-time monitoring for superior performance across marine and industrial projects.

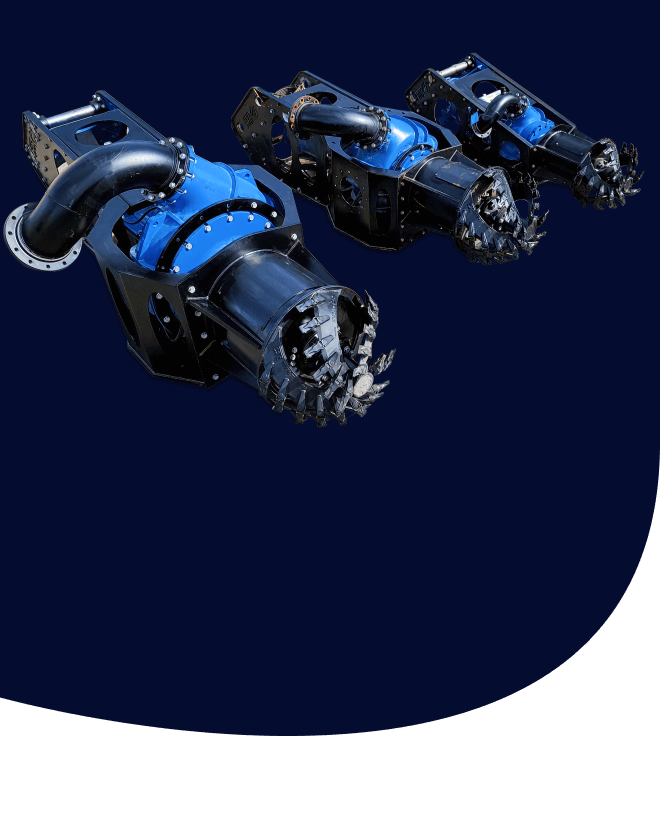

High-Efficiency Excavator Pump Attachments for Dredging

Dredge Georgia integrates advanced excavator pump attachments to enhance dredging efficiency, transforming standard excavators into high-capacity sediment removal systems. Engineered for high-solids pumping, these excavator attachments excel in dredging, sludge removal, and dewatering applications, delivering superior performance with minimal clogging and maximum material throughput.

Available in hydraulic and electric versions, these units provide operational flexibility across various dredging environments. Their heavy-duty construction and advanced pump technology ensure durability and efficiency in handling abrasive slurries, making them critical attachments for excavators in marine, industrial, and environmental dredging projects.

Excavator Pump Attachment Options

- 700-4000 GPM (Up to 350 yd³ per hour)

- Long Reach Dredge Boom

- Dredging Depths of up to 85-ft

- 4-inch, 6-inch, 8-inch, 10-inch, and 12-inch versions

- Cutterhead for compact material dredging

- Water jetting ring option for breakup & agitation

- Liner Safe Option for Dredging Clay, Poly or Concrete Liners

- Power Options. 1. Hydraulically off the Excavator, 2. HPU (Hydraulic Power Unit) or 3. Electrically

- Cutterhead and Non-Clog Head Configurations

- RTK/GPS Precise Position and Dredging

Product Features

- Non-Clogging Design

- High Solids Handling

- High Viscosity and Specific Gravity Handling

- High Abrasives Handling

- No Critical Tolerances

- Low Maintenance

- Minimal Downtime

- Low Ownership Costs

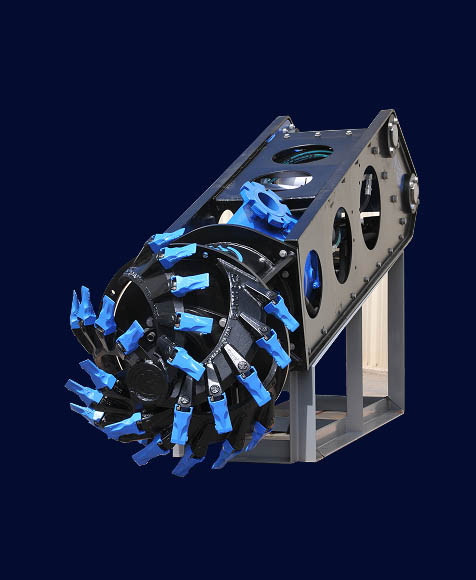

Diver-Operated Dredge Pumps for Precision Underwater Dredging

Dredge Georgia utilizes diver-operated dredge pumps for highly controlled sediment and debris removal in underwater environments. Designed for precision excavation, these submersible systems enable operators to target specific areas with minimal disruption to surrounding structures. Engineered for demanding applications, submersible diver-operated pumps offer superior solids-handling capabilities, ensuring efficient dredging in confined or hard-to-access locations.

Available in diver-operated hydraulic and electric dredge pumps, these units provide flexibility to accommodate various operational needs. The hydraulic models deliver powerful suction and continuous high-performance excavation, while the electric variants offer energy-efficient solutions with reduced maintenance requirements. Ideal for industrial, marine, and environmental dredging, these pumps optimize underwater excavation with unmatched efficiency and reliability.

Excavator Pump Attachment Options

- Non-Clogging Design: Ensures uninterrupted operation in demanding environments.

- Handles High Solids: Efficiently processes large and dense materials.

- Manages High Viscosity & Specific Gravity: Optimized for thick, heavy fluids.

- Durable Against Abrasives: Built to withstand highly abrasive materials.

- No Critical Tolerances: Reduces precision-related wear and failure risks.

- Low Maintenance: Designed for hassle-free upkeep.

- Minimal Downtime: Maximizes productivity with reliable performance.

- Cost-Effective Ownership: Lower operational and maintenance expenses.

Diver Dredge Overview

- Popular Sizes: Available in 4-inch and 6-inch diver dredge models.

- High Solids Handling: Pumps up to 40-60% solids efficiently.

- Multi-Diver Operation: Supports one, two, or three divers simultaneously.

- Extended Reach: Over 300 feet of suction hose for greater flexibility.

- Long-Distance Pumping: Capable of pumping over 2,500 feet.

- Power Options: Available in electric or hydraulic configurations.

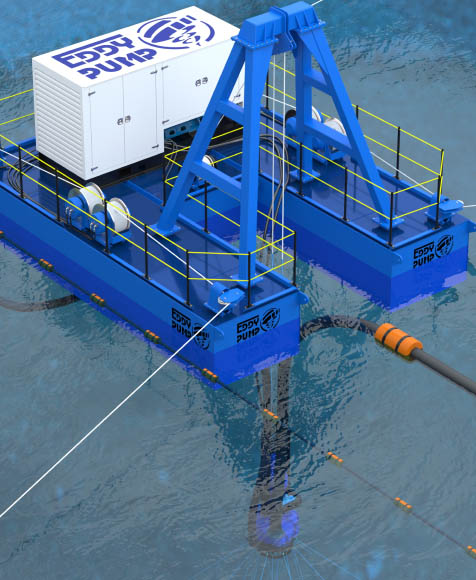

Dredge Sled for High-Efficiency Sediment Removal

Dredge Georgia deploys the Dredge Sled, an advanced sediment removal solution engineered for high-performance pond dredging sled and lagoon dredging sled applications. Designed by EDDY Pump, this system utilizes cutting-edge hydrodynamic principles to efficiently extract accumulated sediments, restoring optimal water depth and quality. Its robust construction and low-maintenance design ensure uninterrupted operation, even in high-viscosity and abrasive environments.

This dredge sled equipment is ideal for large-scale sediment removal dredging sled operations, providing superior mobility, precision, and efficiency. Engineered for minimal environmental impact, it offers an optimal alternative to traditional dredging methods, ensuring cost-effective and sustainable dredging solutions for industrial, municipal, and environmental projects.

- Dredging: Suitable for lakes, canals, lagoons, ponds, rivers, and other waterways.

- Mining: Ideal for process ponds, tailings ponds, and heavy metal recovery applications.

- Wastewater Management: Designed for sedimentation ponds, settling tanks, and digester tanks.

- Energy Sector: Effective for power stations, oil refineries, and fly ash removal.

- Industrial & Manufacturing: Used for chemical storage ponds and dewatering operations.

- Agriculture: Supports lagoon maintenance, pond management, dam clearing, canal upkeep, and desilting.

Cable-Deployed Dredge Pumps for High-Precision Sediment Removal

Dredge Georgia integrates cable-deployed dredge pumps for efficient sediment extraction in complex and hard-to-reach dredging environments. Engineered for deepwater operations, these cable-deployed submersible dredging pumps provide superior solids-handling capabilities, ensuring minimal downtime and optimal material transport. Their advanced hydraulic and electric configurations allow seamless deployment in varying dredging conditions, offering adaptability across industrial, marine, and environmental applications.

Designed for maximum efficiency, cable-deployed hydraulic dredge pumps deliver high-powered excavation with exceptional slurry transport capacity. In contrast, cable-deployed electric dredge pumps provide energy-efficient alternatives with reduced operational costs. These robust dredging solutions ensure reliable performance, making them an essential asset for large-scale sediment removal projects requiring precision, durability, and high throughput.

Typical Applications

- Barge Unloading

- Deep Water Dredging

- Mining

- Sand & Agg

- Oil & Gas

- Fly Ash & Coal Ash

Deploy Via Cable with

- Crane

- A-Frame Barge

- Excavator

Cable-Deployed Dredge Pumps for High-Precision Sediment Removal

Dredge Georgia integrates cable-deployed dredge pumps for efficient sediment extraction in complex and hard-to-reach dredging environments. Engineered for deepwater operations, these cable-deployed submersible dredging pumps provide superior solids-handling capabilities, ensuring minimal downtime and optimal material transport. Their advanced hydraulic and electric configurations allow seamless deployment in varying dredging conditions, offering adaptability across industrial, marine, and environmental applications.

Designed for maximum efficiency, cable-deployed hydraulic dredge pumps deliver high-powered excavation with exceptional slurry transport capacity. In contrast, cable-deployed electric dredge pumps provide energy-efficient alternatives with reduced operational costs. These robust dredging solutions ensure reliable performance, making them an essential asset for large-scale sediment removal projects requiring precision, durability, and high throughput.

Typical Applications

- Barge Unloading

- Deep Water Dredging

- Mining

- Sand & Agg

- Oil & Gas

- Fly Ash & Coal Ash

Deploy Via Cable with

- Crane

- A-Frame Barge

- Excavator

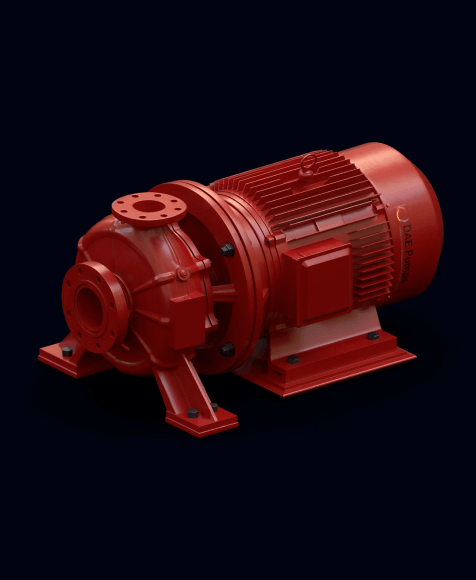

Self-Priming Slurry Pumps for High-Efficiency Dredging

Dredge Georgia deploys self-priming slurry pumps engineered for seamless operation in heavy-duty dredging and material transport applications. These advanced self-priming dredge pumps eliminate the need for manual priming, significantly reducing downtime while ensuring continuous high-performance slurry handling. Designed for versatility, they efficiently manage high-viscosity and abrasive slurries, making them ideal for demanding dredging environments.

Available in both self-priming electric dredge pumps and self-priming diesel-driven dredge pumps, these systems provide tailored solutions for various operational needs. The electric models deliver energy-efficient performance for controlled environments, while the self-priming diesel dredge pumps offer unmatched mobility and power for remote dredging sites. Engineered for reliability and durability, these self-priming pump systems enhance productivity in marine, industrial, and environmental dredging projects.

Self-Priming EDDY Pump Advantages

- EDDY Power in a Self-Priming System: Efficient and reliable performance.

- Continuous Priming: Secondary vacuum pump ensures uninterrupted operation.

- Giant Wet Vac Functionality: Handles tough pumping applications effortlessly.

- High Solids Handling: Moves 30-70% solids with ease.

- Versatile Power Options: Available in electric or diesel configurations.

- Rugged & Non-Clogging Design: Handles high viscosity, high specific gravity, abrasives, and low pH fluids.

- Debris-Resistant: Processes rags, string, rocks, and foreign objects without clogging.

- Flexible Mounting Options: Available in skid, trailer, or stationary setups.

Advanced Remote-Operated Dredging Solutions

Dredge Georgia employs cutting-edge remote-operated dredges to execute high-precision dredging with enhanced safety and efficiency. Designed for crewless operation, these systems utilize advanced remote-control dredging equipment. Operators can manage dredging processes from a secure location while maintaining full control over excavation depth, slurry flow, and material transport. This technology ensures minimal operational risks and maximized productivity in challenging dredging environments.

Engineered for high-performance applications, these remote dredging solutions provide exceptional versatility across industrial, environmental, and marine dredging projects. Their robust construction and automated control systems optimize sediment removal with reduced downtime, making them a critical asset for large-scale dredging operations requiring precision, reliability, and efficiency.

EDDY Pump Advantages

- Remote Operated & Autonomous Dredge: Advanced hands-free operation.

- Rugged & Non-Clogging Design: Handles high viscosity, high specific gravity, abrasives, and low pH fluids.

- High Solids Pumping: Moves 40-70% solids by weight.

- Large Object Handling: Pumps materials up to 12 inches in diameter.

- 100% American Built: Engineered and manufactured in the USA.

- Cutting-Edge R&D Facilities: On-site innovation and development.

- Debris-Resistant: Easily processes rags, string, rocks, and foreign objects.

Pump Features

- Non-Clogging Design: Ensures uninterrupted performance in tough conditions.

- High Solids Handling: Efficiently processes dense and heavy materials.

- Handles High Viscosity & Specific Gravity: Optimized for thick, heavy fluids.

- Durable Against Abrasives: Built to withstand highly abrasive materials.

- No Critical Tolerances: Reduces wear and failure risks.

- Low Maintenance: Designed for easy upkeep and reliability.

- Minimal Downtime: Maximizes productivity with continuous operation.

- Low Ownership Costs: Cost-effective with reduced operational expenses.

High-Performance Earth Moving Equipment for Dredging

Dredge Georgia utilizes a specialized fleet of earth-moving equipment engineered for maximum efficiency in excavation and sediment management. These machines, featuring long-reach excavator kits, provide extended reach and superior maneuverability, ensuring optimal performance in deep excavation and challenging dredging environments. Integrated amphibious undercarriages enhance stability and mobility in soft, waterlogged, and marshy terrain, making them ideal for wetland restoration, shoreline reinforcement, and large-scale dredging projects.

Equipped with RTK GPS positioning systems, these advanced excavators deliver pinpoint accuracy in material placement, excavation depth, and project execution. This cutting-edge technology optimizes efficiency, reduces rework, and enhances overall operational precision, ensuring superior results in dredging, land reclamation, and coastal protection projects.

Long Reach Arm Kit Includes

- Boom x1 unit

- Stick x1 unit

- High-quality hydraulic bucket cylinder x1 unit

- Hydraulic tubing with clamp x1 set

- Hydraulic pressure hose x1 set

- Bucket linkage c/w 2 pins x1 set

- Bucket pin x2 pcs

- Arm cylinder pin x1 pcs

- Yoke pin x1 pcs

- EM bushings

- CE bucket c/w teeth x1 unit

- Seal kit, hydraulic bucket cylinder x1 set

High-Performance Dewatering Pumps for Water Management

Dredge Georgia deploys advanced dewatering pumps engineered for rapid and efficient water removal in dredging, construction, and mining applications. Designed for high-performance operations, these systems include submersible dewatering pumps for deepwater extraction and self-priming dewatering pumps for quick deployment in areas requiring continuous drainage. Their superior solids-handling capabilities ensure smooth operation even in high-sediment environments.

Built for reliability and efficiency, these pumps minimize downtime while maximizing water displacement. They are essential for managing groundwater, stormwater, and slurry-laden discharge. With robust construction and non-clogging technology, these dewatering solutions enhance productivity and ensure seamless water control across a range of industrial and environmental projects.

Frequently Asked Questions

Dredge Georgia provides comprehensive dredging solutions, including hydraulic and mechanical dredging, sediment removal, shoreline restoration, pond and lagoon dredging, harbor maintenance, and industrial dredging. We specialize in tailored dredging projects to meet the unique challenges of marine, riverine, and industrial environments.

Yes, we provide marine dredging services for ports, harbors, and coastal restoration projects. Our advanced dredging equipment ensures efficient sediment removal and depth maintenance while minimizing environmental impact.

We utilize high-performance dredging equipment, including hydraulic and mechanical dredges, excavator pump attachments, self-priming slurry pumps, dewatering pumps, and remote-operated dredges. Our fleet features cutting-edge technology to handle high-viscosity materials, abrasive sediments, and complex dredging conditions.

Yes, we offer specialized industrial dredging services for power plants, chemical facilities, paper mills, and other industrial sites. Our excavator attachments, self-priming dredge pumps, and diver-operated dredge pumps are designed for efficient sludge and slurry removal, ensuring smooth operations.

Dredge Georgia stands out due to our technical expertise, advanced equipment, and customized dredging solutions. We emphasize efficiency, minimal downtime, and environmental compliance while delivering superior dredging services tailored to each project’s requirements.

Absolutely. Our remote-operated dredging equipment, diver-operated dredge pumps, and amphibious dredging systems allow us to operate efficiently in confined or environmentally sensitive areas, ensuring precision dredging with minimal ecological disturbance.

Yes, we integrate long-reach excavators, amphibious undercarriages, and RTK GPS positioning systems to support dredging and earth-moving operations. These systems enhance accuracy and efficiency in material excavation and transport.

Yes, we provide submersible and self-priming dewatering pumps for efficient water management in dredging projects. These systems help control excess water and maintain optimal working conditions for excavation and sediment removal.

We use excavator pump attachments, cable-deployed dredge pumps, and self-priming slurry pumps, available in hydraulic and electric configurations. Our pumps are engineered for high-solids handling, reduced clogging, and superior performance in dredging applications.

You can contact Dredge Georgia through our website or by phone to schedule a consultation. Our team will assess your project needs and provide tailored dredging solutions to ensure efficiency, cost-effectiveness, and environmental compliance.

Starting a dredging project but unsure where to begin?

Let’s get started! Share your project details, and our dredging experts will craft a seamless, customized plan.